In the world of mountain biking, pushing boundaries and mastering new tricks is part of the thrill. But as riders soar higher and attempt more complex maneuvers, safety becomes paramount. That’s where MTB jump airbags come in, providing a forgiving landing zone that allows athletes to progress their skills without the fear of serious injury.

However, not all jump airbags are created equal. The material used in their construction plays a crucial role in their performance, durability, and overall safety. Choosing the right airbag is an investment in your riders’ well-being and the longevity of your equipment.

This comprehensive guide delves into the intricacies of MTB jump airbag materials, exploring the industry standard, the factors that influence quality, and additional features that enhance performance.

PVC Coated Mesh Fabric: The Foundation of Airbag Landing

The vast majority of airbag landings on the market today are made from PVC coated mesh fabric, also known as PVC tarpaulin. This material has become the industry standard due to its unique combination of properties:

- Strength: The PVC coating provides excellent tear resistance, ensuring the airbag can withstand the impact of repeated landings.

- Flexibility: The mesh fabric allows the airbag to flex and conform to the shape of the landing rider, providing a more comfortable and controlled landing experience.

- Waterproof: The PVC coating makes the airbag impervious to water, making it suitable for use in various weather conditions.

- Easy Maintenance: The smooth PVC surface is easy to clean and maintain, ensuring a hygienic and long-lasting landing surface.

- Affordability: PVC coated mesh fabric is a cost-effective material, making it a practical choice for both small and large-scale airbag landings.

Deconstructing PVC Mesh Fabric: A Closer Look

Understanding the construction of PVC coated mesh fabric is essential for evaluating its quality and suitability for MTB jump airbag applications. As the name suggests, this material consists of three layers:

- Outer PVC Layer: This layer, typically made from a durable PVC (Polyvinyl Chloride) film, provides the primary protection against tearing, abrasion, and water penetration. It also gives the airbag its smooth, easy-to-clean surface.

- Inner Mesh Layer: This layer, made from a woven polyester or nylon fabric, provides the structural strength and reinforcement for the airbag. The mesh structure allows the airbag to flex and deform under impact, distributing the force of the landing evenly.

- Inner PVC Layer: A second layer of PVC is applied to the backside of the mesh, providing additional waterproofing and abrasion resistance. This layer also helps to seal the air inside the airbag, preventing leaks and maintaining its shape.

Factors That Influence Quality: Thickness, Brand, and Webbing

The quality of PVC coated mesh fabric can vary significantly between suppliers. Here are the key factors to consider when evaluating this material:

- Thickness: The thickness of the PVC coating and the mesh layer directly impact the airbag’s durability and performance. Thicker materials generally offer greater tear resistance, puncture resistance, and impact absorption capabilities. Look for airbags with a PVC coating of at least 0.55mm and a strong, densely woven mesh layer.

- Brand: The brand of PVC used in the coating can also influence the material’s quality. Reputable brands like PLATO (a leading PVC manufacturer in China) are known for producing high-quality PVC that meets stringent industry standards for durability, UV resistance, and flame retardancy.

- Webbing Reinforcement: Some manufacturers add webbing to reinforce the seams and stress points of the airbag. This webbing can be made from different materials, but PVC webbing is generally considered the most durable option. The thickness of the webbing, measured in denier (D), also matters. Look for webbing with a high denier count, such as 1000D, for added strength and longevity.

The Importance of Top Sheets

The topsheet is the top layer of the airbag that riders directly contact upon landing. It needs to be exceptionally durable, smooth, and designed to withstand repeated impacts and abrasion from snowboard bindings, ski edges, and other equipment.

Most MTB jump airbags utilize a PVC topsheet with a thickness of 0.9mm or greater. Some manufacturers offer premium topsheets made from PVDF (Polyvinylidene Fluoride), which is known for its exceptional abrasion resistance, UV resistance, and longevity.

Choosing the Right Airbag Landing: A Smart Investment

Investing in a high-quality airbag landing is essential for the safety of your riders and the success of your business. By understanding the materials, construction, and key features to look for, you can make an informed decision that will provide you with years of reliable and safe service.

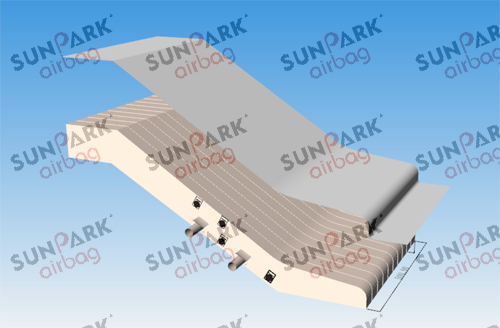

Don’t hesitate to contact reputable airbag landing manufacturers like SunparkAirbag to discuss your specific needs and requirements. They can guide you through the selection process and help you choose the best airbag solution for your facility.

By prioritizing quality, safety, and performance, you can create a training environment that empowers athletes to reach their full potential while minimizing the risk of injury.